PRODUCTS

- Panel Saw>

- Edge Banding Machine>

- Drilling Machine>

- CNC Router

- No Paint Machines>

- Paint Finishing System>

- Sanding Machine Series>

- Drum Sander Series

- Saw Series>

- Planer And Thicknesser>

- Finger Joint Machine>

- Press Machine>

- Spindle Moulder

- Mortising Machine>

- Knife Sharpening Machine>

- Woodworking Tool>

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

Product recommended

Hotline:

86-532-67703247

Email: 86-532-68067870

Phone: 86-18653228838

Address: Yanjialing Industrial Park, Tongji Office, Jimo, Qingdao, Shandong, China

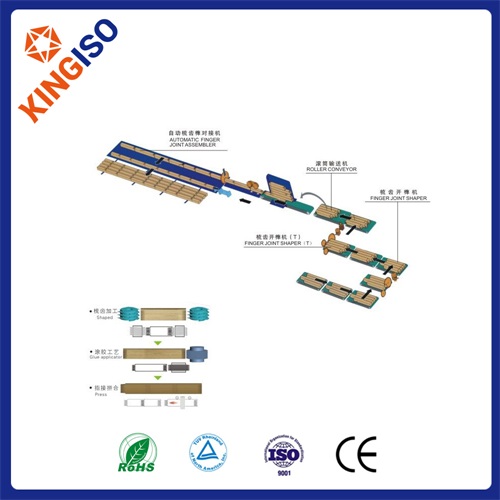

JQ Finger Joint Line Woodworking Machinery

- JQ Finger Joint Line Woodworking Machinery Parameters:ModelMXZ3515 Finger joint shaperMXZ3

- Hotline: 86-532-67703247

- Fax: 86-532-68067870

- Email:mike@kingiso.com

Detail

Contact Us

JQ Finger Joint Line Woodworking Machinery

Parameters:

Model | MXZ3515 Finger joint shaper | MXZ3515T Finger joint shaper with automatic gluing device |

Table Size(LxW) | 850x600mm | 850x600mm |

Max working size(LxWxH) | 850x80x150mm | 850x80x150mm |

Min working thickness | 150x20x30mm | 150x20x30mm |

Cutter speed | 6000r/min | 6000r/min |

Draw saw speed | 5600r/min | 5600r/min |

Trimming saw speed | 5000r/min | 5000r/min |

Shaper blade diameter | 160mm | 160mm |

Shaper spindle diameter | 70mm | 70mm |

Main saw blade size | 255mm | 255mm |

Cutter motor power | 11kw | 11kw |

Saw motor power | 5.5kw | 5.5kw |

Feeder motor power | 0.375kw | 0.375kw |

Total power | 16.12kw | 16.87kw |

Working air pressure | 0.5-0.8Mpa | 0.5-0.8Mpa |

Net weight | 2000kg | 2200kg |

Overall diamensions | 2380×1700×1400mm | 2580×1700×1400mm |

Model | MHB1560 Finger joint assembler |

Max.assembled size | 6200x150x80mm |

Max.working length one time | 6200mm |

Max.working width | 150mm |

Max.working thickness | 80mm |

Min.working length | 2000 mm |

Min.working width | 30mm |

Min.working thickness | 20mm |

Blade speed | 3700r/min |

Saw blade dia | 355 mm |

Saw blade power | 3kw |

Oil pump motor power | 5.5kw |

Working air pressure | 0.5-0.8Mpa |

Max.thrust for oil pressure | 7800Kg |

Max.output | 25m/min |

Overall diamensions | 4700×1000×1420mm |

The Feature :

1.Guide rail of finger joint shaper’s conveyor is japan precision linear guide rail to gurantee the shaping accuracy .

2.The design for finger joint shaper is double blades+tooth-tenon knife assembly to provide high precision.

3.The conveyor table of finger joint shaper adopts German pneumatic hydraulic conveyor system to control bakc and forth ,smoothly,low maintenance,high quality .

4.The second push part of finger joint assembler adopts long+short double pushing board design,by this kind of structure ,it can assemble very short workpiece to reduce the cost .

5.Whole machine is conveniently operated by PLC Central integrated programmable controller.