PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

MJ1435D Multi-blade round sawing machine

- Video DescriptionMJ1435D Multi-blade round sawing machine for woodworking machineryProduct Descripti

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Video Description

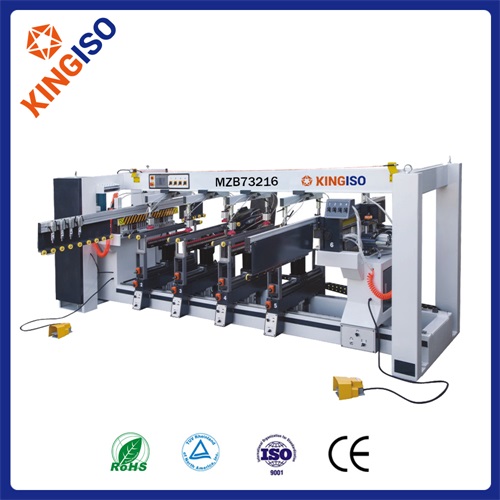

MJ1435D Multi-blade round sawing machine for woodworking machinery

Product Description

Working thickness | 10-100mm |

Max working width | 300mm |

Min working length(continual feeding) | 210mm |

Feed speed | 6-30m/min |

Saw spindle speed | 3600r/min |

Suitable saw blade diameter | (φ250-φ355)xφ70x(2-3.2)mmm |

Main motor power | 30kw(22kw) |

Feed motor | 2.2kw |

Total motor power | 33.3kw(25.3kw) |

Feeding reack elevating motor power | 0.55kw |

Saw frame lifting motor power | 0.55kw |

Machine dimension | 2420x1180x1500mm |

Weight | 1600kg |

Features

1.This machine uses upper and lower power roller,driven by worm gear speed reducer,and actuated by universal joint to ensure feeding smooth and strong.

2.Upper feeding roller controlled by pressure air cylinder,and you can free to adjust according to the hardness of the timber.

The feeding speed is Frequency conversion control,the viewable digital display shows the feeding speed,easy to understand.

The laser marker instrument indicate the blade position accurately.

Protective device for elevation of saw blade can safety limit with the lifting feeding roller and saw blade,to prevent the damage from misopearation.

3.The special design,making the across bridge plate is no longer have to process comlicated dovetail chute.

4.Special alloy steel material used for the saw shaft, through multiple times of heat treatment and a special process with precision.

5.The special designed blade cooling device,the atomizated cooling liquid can direct spary to the blade,thereby increase the service life of the saw blade.

6.The upper and lower non-return device to prevent the wood chips rebound.

7.Feeding roller has a sawdust removal device which can remove the sawdust adhere to the deeding roller surface quickly,to ensure smooth feeding.

8.Concentrated lubricated system directly supply lubricating oil to lifting column,the feeding roller arm,dovetail guide,the swing shaft of the motor plate.Each shift operator simply shake the handle, the lubricating will be transpoted to all parts,so maintenance is simple and easy.

9.The pulley uses keyless structure,and it easy to complete installation and maintence

Detailed Images

Factory Warehouse

Our customers

Our Services

1.Good after-sale Services is our strength

1) The machine guarantee is 12 months.

2) 24 hours technical support by email or calling.

3) Friendly English version manual and operation video CD disc.

4)Our engineers can provide services to overseas.

2.Main Market

Which have been exported to a lot of country and Regions . Such as Europe , Russia, Southeast Asia . Middle East . North America

and south America , Australia .

3.Sample Service :

If you want to test the performance of machine ,we can sent sample to you with cost offer .

4.Customized Service :

Our factory has been specialized in producing woodworking machines for over 33 years .We have very high research and development capabilities to meet the requirements of custom

5.We have years of manufacturing woodworking machine,OEM and ODM service available.

FAQ

1) Q: What's the MOQ?

A: MOQ is one set.

2) Q: Provide custom machine Yes or No?

A: Yes. We can provide custom machine for clients.

3) Q: What's the payment terms?

A: T/T 30% in advance and balance before shipment or by negotiation.

4) Q: Are you factory or trade company?

A: We are factory and trade company. KINGISO is our brand.

5) Q: How long is the warranty period?

A: One year warranty period except the quick-wear parts.

6) Q: Do you have professional engineers?

A: Yes. We have professional engineers and designers. We can provide OEM products.