PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

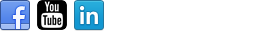

MJK1327FG CNC panel saw

- Application:Apply to processing all kinds of density boards, shaving boards, wood-based panels, ABS

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Application:

Apply to processing all kinds of density boards, shaving boards, wood-based panels, ABS panels, PVC panels, organic glass plates and solid wood and others with wood structure and similar hardness.

Features:

1.Using precision linear slide rail, strong stability, high precision.

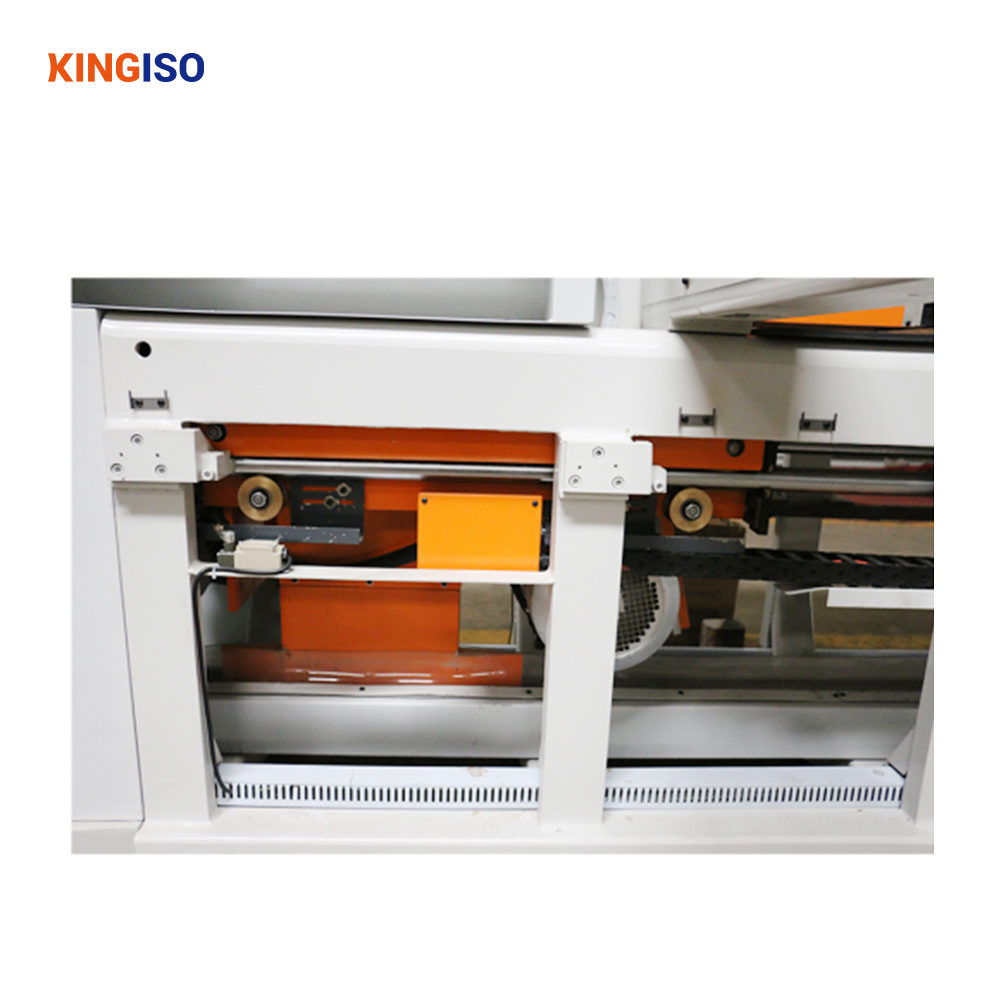

2.PC Control System

3.Sheet metal clip is expected to adopt cylinder and feed forward through the roller bed surface, feeding and accurate, and ensure that saw cutting precision, and will not hurt the workpiece surface.

4.Floating effect of the floating platform is caused by the pressure, to facilitate feeding, especially suitable for the heavy plate, and can avoid the surface damage.

5.Automatic sheets-feeder with Japan's Mitsubishi high-performance servo motor drive, big torque, accurate positioning and long service life.

6.High quality Japanese Mitsubishi CPU control main board.

7.The machine adopts imported magnetic feet as feed positioning detection control, precise positioning detection size effectively, improve the cutting precision.

8.Advanced reasonable electrical control design, equipment can be realized automatically return, to ensure the safety of the processing efficiency.

9.Adopt Taiwan precision gear and rack, durable.

10.Speed of saw carriage can reach 5-100m/min

11.Speed adjustable for forward moving of saw carriage.

Advantage:

1. Pneumatic compressed feeding roller is applied, the pressing force can be adjusted by stages which is favorable for smooth feeding of timbers with different thickness.

2. International brands electrical parts are applied for good stability.

3. Spare parts are thick and solid to maintain high precision, high stability and reliability.

4. Completely sealed safety shield can avoid flying of saw dust and isolate noise efficiency and protect operators.

5.Mass production is several times more efficient than common machinery and saves time and power.

Product Description

Model | MJK1328FG |

Max cutting length | 2780mm |

Max.cutting thickness | 95mm |

Main saw blade diameter | Φ380/400mm |

Main saw shaft diameter | Φ60mm |

Main saw rotating speed | 4800rpm |

Scoring saw blade diameter | Φ180mm |

Scoring saw blade inner diameter | Φ30mm |

Scoring saw rotating speed | 6500rpm |

Saw carriage forward speed adjustable | 0-80m/min |

Saw carriage backward speed | 0-100m/min |

Main saw motor | 16kw |

Saw carriage driving motor | 2.2kw |

Automatic feeding motor | 1.5kw(AC Servo motor) |

Total power | 21.9kw |

Automatic feeding speed | 80m/min |

Air pressure | 5-7kg/cm² |

Working table height from ground level | 960mm |

Net weight | 4500kg |

Gross weight | 4600kg |

Overall dimension | 5100x5900x1810mm |

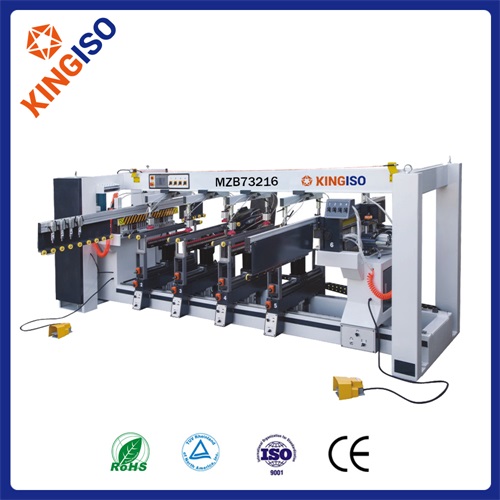

Detailed Images

Finshed Products