PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

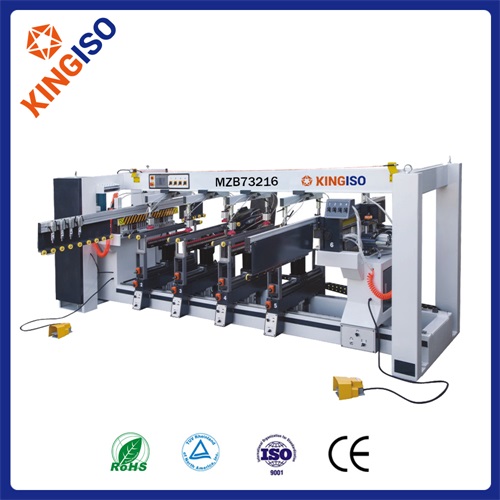

KI9440 Multifunctional Double Sides Planer Multiple Rip Saw Wood Floor Making Machine

- Technical Parameters:ModelKI9440MAX working Width400mmMAX working Thickness20-100mmInfeed speed6-18m

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Technical Parameters:

Model | KI9440 |

MAX working Width | 400mm |

MAX working Thickness | 20-100mm |

Infeed speed | 6-18m/min |

Upper horizontal axis speed | 6000r/min |

Donw horizontal axis speed | 6000r/min |

Cutting spindle speed | 3600r/min |

Upper horizontal axis diameter | 50mm |

Lower horizontal axis diameter | 50mm |

Saw spindle diameter | 50mm |

Saw blade diameter | 300-350mm |

Upper horizontal shaft motor power | 11kw |

Lower horizontal shaft motor power | 5.5kw |

Saw shaft lift motor power | 0.37kw |

Bed cover lift motor power | 0.75kw |

Feed motor power | 5.5kw |

Total power | 60.12kw |

Air pressure | 0.6Mpa |

Outline dimension | 4000*1350*1600mm |

Machine weight | 4200kg |

Performance :

1.steel wheal in multi quantities

2.Glue system wheel in multi quantities

3.Adujstable working mesa and dampers

4.Toothed transmission wheel

5.Standard:alloy flat head

6.Optional:alloy spiral cutter

Function:

1.Through the workpiece under high speed cutter head level cutting processing,the first step to complete.

2.By trimming cutting the workpiece on the right edge processing,and broken sawdust ,complete the second process

3.Through high speed cutter head of workpieces planning process,complete the third process.

4.Through multiple cutting and sawing it complete finishing fourth synchonous chip discharging process.