PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

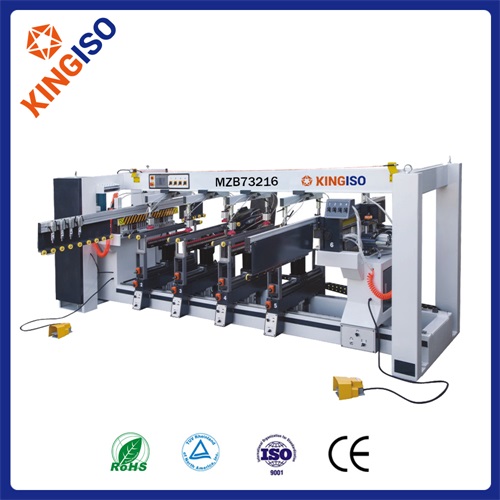

HF(RF) Wooden Frame Jointing Machine

- Function: This machine is suitable for fast assembling of all kinds of wooden frame, with or without

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Function: This machine is suitable for fast assembling of all kinds of wooden frame, with or without tenon, such as closet door, cabinet door, furniture frame assembly, drawer, mirror frame, and picture frame, which adopts high frequency power heating, four-angle pressurized mode.

High speed: glue is solidfied in 2-20 seconds, and it can operate on the assembly line.

Saving labor: it saves a lot of times for loading and checking, and operate without fixtures.

High quality: no need to use staple gun and improved subsequent procedures, the glue can be solidfied under high pressure.

High pression: it adopts the ball screw and precision linear guide, and controls the machine with moter, diagonal error minimization.

Low cost: a frame only costs about 0.003-0.04 KWh.

Convenience: it adopts touch screen of human-machine interface, easy change the dimension automatically, PLC automatically control, all data can display on touch screen, including pressure, current, heating time and cooling time, etc.

Technical Data:

Type | CGZK-1200*800 | CGZK-2000*800 | CGZK-2800*800 | CGZK-2800*1000 | CGZK-3400*1200 | |

Max.working size(mm) | 1200*800 | 2000*800 | 2800*800 | 2800*1000 | 3400*1200 | |

Min.working size(mm) | 80*80 | 130*130 | 130*130 | 130*130 | 200*200 | |

Pressurizing mode | Precision lead screw | |||||

Overall dimension(mm) | 2000(L)*1180(W)*1750(H) | 2760(L)*1180(W)*1750(H) | 3560(L)*1180(W)*1750(H) | 3560(L)*1380(W)*1750(H) | 4160(L)*1580(W)*1750(H) | |

Weight(t) | 0.8 | 1.5 | 2 | 2.2 | 2.5 | |

New product recommend:

1.Thickening worktable, higher rigidity ensures worktable stabilization during assembling.

2.10 inch touch screen, larger word, simple operation and high grade equipment.

3.Using the organ shield reduces damage to the ball screw and guide rail.

4.Position of positive pole can be adjustied, in order to assemble the smaller wooden frame.

5.The mounting surface of the guide rail adopts precise scrping technology to ensure the flatness of the four pcs of moving upper sliding plate, and ensures the high quality of the workpieces.

6.Software function is powerful, the interface is friendly, can realize the “日” type door middle line assembly, heating, electric current completely automatic adjustment.

THE OPTIONAL 1

Remark: this machine equipped with the portal frame, and can join the frame of “日” shape, and”目”shape. six point heating, the related should add ”-L” behind the model number.

THE OPTIONAL 2

Top pressure adopts piano type structure, which ensure flatness of workpiece, and remove error of angle degree because of different thinkness wood strips. (note. The coating door assembly is the final process), the related should add “-S” behind the model number.

THE OPTIONAL 3

Y axis transmission system adopts accurancy liner guide, which mostly reduce slide plate to deform during assembling (degree of accuracy is lower from 0.2mm to 0.015mm). and mostly improve stability of machine and assembling quality of workprice, the related should add “-E” behind the model number.

THE OPTIONAL 4

The machine can be equipped with auto-unloading system, completed assembled door will be automatic sent out, which suitable for production line, and improves 20%-30% working effeciency for bartch production, the related should add “-B” behind the model number.