PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

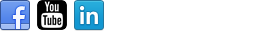

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

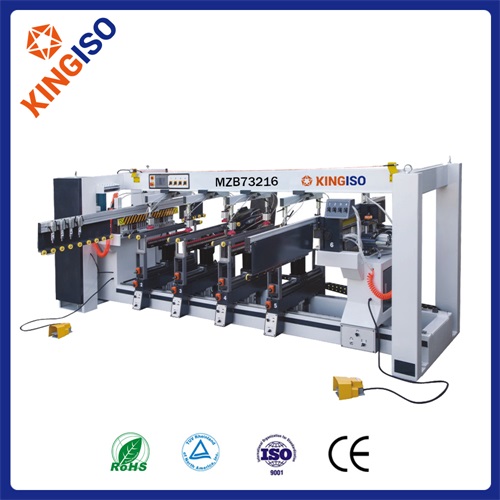

High Frequency board jointing machine for woodworking

- High Frequency board jointing machine for woodworkingProduct Description Main technical specifi

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

High Frequency board jointing machine for woodworking

Product Description

Main technical specifications

Workbench size | 1300 ×5000mm |

working thickness(mm) | 10-80 |

Feeding &discharging mode | AUTO |

Upper pressure | 48T |

Diameter of upper cylinder | Φ80x400 |

upper cylinder number | 6 |

Back pressure | 62T |

Diameter of Back cylinder | Φ50x100 |

Back cylinder number | 20 |

Feeding Type | Push type |

Motor power | 70KVA |

Overall dimension(mm) | 8700x4400x2300mm |

Weight | 13t |

Function and advantages

1.Standard technology efficiency: 2-3mins per board, working efficiency will be more improved than common press machine in winter.

2.Feeding table adopts PVC plate,which will reduce friction,discharge table adopts no power chrome plating roller, high efficiency.

3.Unloading is outside of machine which will be safety and coinvent.

4.oil box length of hydraulic system will be 2570mm,which will be good heat dissipation, avoid high oil temperature shortening hydraulic oil service life. Then improve stability of hydraulic system.

5.Hydraulic pipe jointer adopts inch cone sealing structure, no using sealing ring ,which resolve the oil leaking by using sealing ring .

6.Each oil pressure can be adjusted separately by reducing pressure valve, then realized stable performance, so that it deleted the control pressure meter is out of work problems.

Machine rack adopts heavy structure.Then make sure the higher straightness accuracy of finished board

7,High frequency generator installs the high sensitive spark protective circuit, it is effective to protect board damaged.

8.Bug-killing and sterilization

9. Joint plate is high in plainness and quality ,the percentage of outturn is more inproving 5%than the common machine.

10.Convenient handling and low labor intensity

11. Selective heating, glue line heated with low heat in timber, energy saving, little distortion, only cost 15-30KW.h for 1m³board.

12.Assemble varieties of materials such as soft and hard article Board, medium density fiber board, etc

13.It can check the Higher water content of splicing board material, then ensure the product quality after finishing.

14, it is installed the exported glue clearance sheet on the worktable, which will be easy to clear the rest glue .

15. High frequency generator is outside of HF board jointing machine ,and lays the back of board jointing machine which will be easy to maintain.

Packaging & Shipping

1.The Packaging Details: Stretch film with wooden case or as your request

2.Shipping:We have rich experience in exporting machines to the world and can supply all kinds of different shipping terms!

3.Timely delivery and transportation