PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

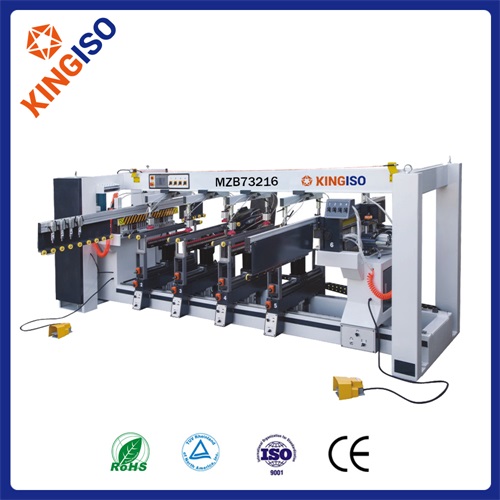

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

KICC-250D CNC Custom Carton Cutting Machine

- Technical Parameter:Carton Cutting Size Carton width200-1200mmCarton length400-2500mmCart

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Technical Parameter:

Carton Cutting Size |

|

Carton width | 200-1200mm |

Carton length | 400-2500mm |

Carton thickness | 25-600mm |

Corrugated paper specifications | |

Single-layer corrugated / double-layer corrugated | thickness/2.0-7.0mm |

Corrugated paper in raw material area | |

Corrugated paper stacking quantity | 1-6(pile) |

Corrugated paper stacking range | 800-2500/mm |

Cutting Speed | |

Max horizontal cutting speed | 90m/min |

Max vertical cutting speed | 90m/min |

Servo motor configuration | |

Horizontal cutter motor power | 400W |

Vertical cutter motor power | 400Wx8 |

Feeding motor power | 3KW |

Material selection motor power | 750W |

Total power | 7.5KW |

Production Efficiency | 4-8pcs/min |

Air pressure | 0.5-0.6MPa |

Overall dimension | 15000x3800x3000mm |

weight | 3000kg |

Main parts:

1. The fuselage is solid and heavy structural steel, which is annealed to relieve stress.

The rack and pinion are made of grinding-grade high-precision materials, and are hardened after heat treatment.

2. Relay: Schneider;

3. Sensor: OMRON / AirTAC;

4. Low-voltage electrical and pneumatic components: Schneider;

5. Servo motor: High-precision Haichuang absolute servo motor (Avoid turning back to the origin);

6. Inverter: Taiwan Delta;

7, linear guide, ball screw: Taiwan HIWIN;

8. Gear rack: Taiwan JT.

Feature:

1. The disc flat knife replaces the saw blade, which has a long service life;

2. Indentation cutting without dust, no need for dust collection system;

3. The cut of corrugated paper is smooth after cutting;

4. Constant gap ensures no contact between the cutter and the all-steel backing plate, and the mission life is long

5. Horizontal-cutting knife:

Horizontal cutter shaft: 1 shaft;

Horizontal cutting knife: 1 standard dashed cross-cutting knife; 1 standard cutting knife

Vertical knife:

Vertical knife shaft: 1 shaft;

Vertical knife: 6 standard dotted crimping blades; 6 standard cutting blades, of which 1 is a fixed trimming blade and the other 5 are servo-controlled6. Corrugated paper continuous and efficient processing.

Attached tool layout:: International standard carton:

Operation System:

1.Windows system;

2. Professional operating system for packaging line;

3. (Higerman / PA system) German technology;

4.19-inch high-definition capacitive screen;

Device data read mode:

1. Comprehensive management information of the software docking factory (such as two-dimensional code, bar code);

2. The software receives the data from the measurement station;

3. Read quasi-formatted XLS files;

4. The operator inputs the data directly.

-Soft key functions

Appearance characteristics:

The design looks simple and generous, and the internal combination is compact and reasonable.