PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

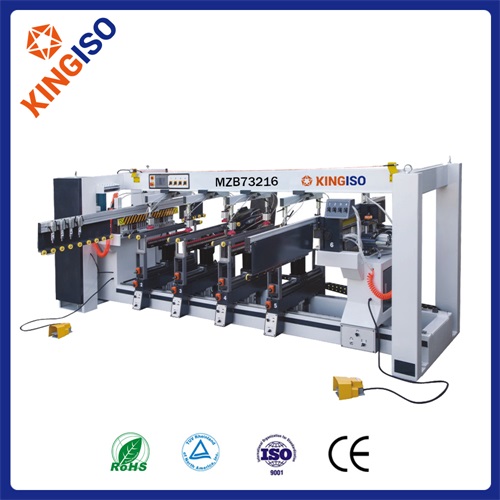

KHD7625 Double End Saw With Vertical Spindle

- KHD7625 Double End Saw With Vertical SpindleTechnical parameter:Max. Working width2500mmMin. Working

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

KHD7625 Double End Saw With Vertical Spindle

Technical parameter:

Max. Working width | 2500mm |

Min. Working length | 250mm |

Max. Working thickness | 80mm |

Min.Working thickness | 6mm |

Cutting circle of scoring saw unit(left and right) | Φ200mm |

Cutting circle of cut-off saw unit(left and right) | Φ300mm |

Cutting circle of milling cutter(left and right) | Φ140-Φ160mm |

Spindle diameter of scoring saw unit(left and right) | Φ25.4mm |

Spindle diameter of cut-off saw unit(left and right) | Φ30mm |

Spindle diameter of milling cutter(left and right) | Φ40mm |

Saw blade speed | 2900rpm |

Spindle speed | 7500rpm |

Scoring saw unit motor power | 2x2.2kw |

Cut-off saw motor power | 2x4kw |

Milling cutter motor power | 2x5.5kw |

Feeding motor power | 3kw |

Widen motor power | 0.25kw |

Total motor power | 27kw |

Feeding speed | 5-18m/min |

Dust pipe diameter | Φ100x4 andΦ60x2 |

Over size | 4350*2600*1600mm |

Weight | 4800kg |

Function:

This machine used for wood floors,wood laminate floor, laminate floor, solid wood furniture, doors and windows , double end saw , tenon trimming and planing and so on.

Advantage:

1.Each spindle can rotate, convenient to achieve angle-truncate, tenon, groove and etc.

Drunken saw with jump saw function can reduce burr and side damage.

2.Installed crushing blade is helpful for the eductions of sheet metal and edge material.

Adopted widen by high precision linear orbit, machine can run in precision and wearable. It assure the precision when widen the working size, also can guarantee to fit your highly requirement for setting the working width.

3.Orbit lubrication can reduce the frictions of slide when moving, increase the nature life of orbit as well.

4.Supported with the roller bearing in the feeding belt, make the movement more stable and reduce the noise.

5.Much better to infeed the big size panels with the lengthen chain belt design.

In order to assure every chain board with high precision, we use the high hardness cast iron and treated with high temperature and machining by CNC.

6.Each spindle is equired with high precision bearing, spindle speed of milling units reach to 7500r/min.

7.Text controller adjusts the wide, reset accuracy of t 0.1 mm.

8.Each spindle is configureed with read out, can display the position of spindle veracious.

9.Adopted inverter for feeding, make the feed speed reaches t0 5-25m/min.

10.Adopted the high class electric component to build up the perfect electic system can increase the stabili zation.

11.Adopted excellent material to make of the pressure belt, keep good wearable.

12.Sealed safety enclosure can reduce noise levels, improve extraction and operator safety.

13.Guide rail safety enclosure assures the adjustion lead screw avoid sawdust pollution.