PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

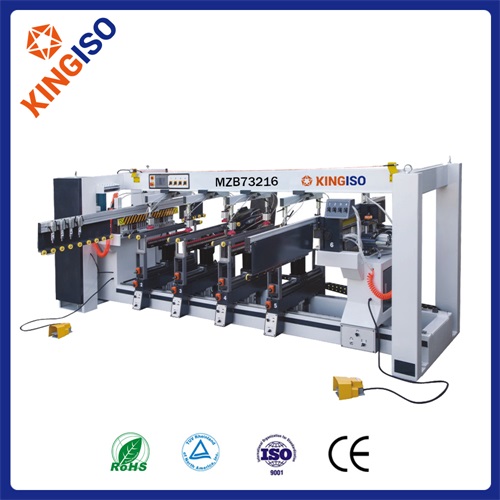

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

MJK1333F Computer Panel Saw

- Technical ParameterModelMJK1333FMax cutting length3280mmMax.cutting thickness100

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

Technical Parameter

Model | MJK1333F |

Max cutting length | 3280mm |

Max.cutting thickness | 100mm |

Main saw blade diameter | Φ400mm |

Main saw blade inner diameter | Φ30mm |

Main saw rotating speed | 4800rpm |

Scoring saw blade diameter | Φ180mm |

Scoring saw blade inner diameter | Φ30mm |

Scoring saw rotating speed | 6500rpm |

Saw carriage forward speed adjustable | 0-100m/min |

Saw carriage backward speed | 0-150m/min |

Main saw motor | 15kw |

Saw carriage driving motor | 2.2kw |

Automatic feeding motor | 1.5kw(AC Servo motor) |

Total power | 20.9kw |

Automatic feeding speed | 80m/min |

Air pressure | 5-7kg/cm² |

Working table height from ground level | 960mm |

Net weight | 5000kg |

Gross weight | 5200kg |

Overall dimension | 5830x6500x1810mm |

Feature:

1.Using precision linear slide rail, strong stability, high precision.

2.Japan's Fuji display.

3.Sheet metal clip is expected to adopt cylinder and feed forward through the roller bed surface, feeding and accurate, and ensure that saw cutting precision, and will not hurt the workpiece surface.

4.Floating effect of the floating platform is caused by the pressure, to facilitate feeding, especially suitable for the heavy plate, and can avoid the surface damage.

5.Automatic sheets-feeder with Japan's Mitsubishi high-performance servo motor drive, big torque, accurate positioning and long service life.

6.High quality Japanese Mitsubishi CPU control main board.

7.The machine adopts imported magnetic feet as feed positioning detection control, precise positioning detection size effectively, improve the cutting precision.

8.Advanced reasonable electrical control design, equipment can be realized automatically return, to ensure the safety of the processing efficiency.

9.Adopt Taiwan precision gear and rack, durable.

10.Speed of saw carriage can reach 5-100m/min

11.Speed adjustable for forward moving of saw carriage.

Factory Warehouse:

Customers with us:

Packaging & Shipping

1.The Packaging Details: Stretch film with wooden case or as your request

2.Shipping:We have rich experience in exporting machines to the world and can supply all kinds of different shipping terms!

3.Timely delivery and transportation

Our Services

1.Good after-sale Services is our strength

1) The machine guarantee is 12 months.

2) 24 hours technical support by email or calling.

3) Friendly English version manual and operation video CD disc.

4)Our engineers can provide services to overseas.

2.Main Market

Which have been exported to a lot of country and Regions . Such as Europe , Russia, Southeast Asia . Middle East . North America and south America , Australia .

3.Sample Service :

If you want to test the performance of machine ,we can sent sample to you with cost offer .

4.Customized Service :

Our factory has been specialized in producing woodworking machines for over 33 years .We have very high research and development capabilities to meet the requirements of custom.

5.We have years of manufacturing woodworking machine,OEM and ODM service available.

Company Information:

QINGDAO WEICHANG INDUSTRY AND TRADE CO.,LTD is one of the leading companies in woodworking machinery industry, and is highly recognized for its Panel Saw ,Edge Banding Machine,CNC Router,Drilling Machine,Sander Machine ,Polish Machine and Cold Press etc. WEICHANG possesses two production bases, i.e. One is the largest base for manufacturing precise panel saw ,edge banding machine ,drilling machine and CNC Router in China.The other one is the best strength professional manufacturer in sander & polish machine and cold press industry .

Over several decades of development, the group company owns 25,000 square meters of production scale. Besides, it has abundant technique strength, full range of testing method and three professional production lines of woodworking machinery. So it can manufacture thousands sets at the same time. The company has got ISO9001 international system certificate and CE security certificate.

Also we are able to offer comprehensive woodworking machinery solution for various clients. We aim to assist our partners in sourcing whole range machines in China.

To be the world's leading woodworking machinery solution provider is our company vision.

Our products are exported to more than 70 countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, Australia. It has established complete sales system (more than 30 dealers). Over yeas of experience in competitions in domestic and overseas markets, our KINGISO brand has become one of global well-know brand, which offers trustworthy machinery for global customers.

With high credit standing ,best quality and service system, and the competitive price policy, we sincerely look forward to establishing a stable long-term strategical business cooperation with you.