PRODUCTS

- Edge Banding Machine

- CNC Cutting Machine

- Computer Panel Saw

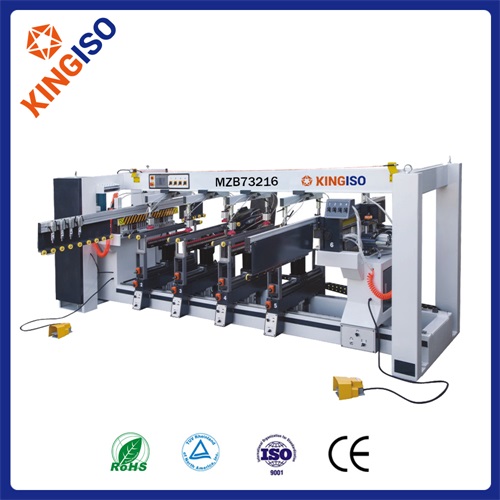

- CNC Drilling Machine>

- Sliding Table Saw

- Other Machine>

- Drilling Machine

- No Paint Machines

- Paint Finishing System

- Sanding Machine Series

- Drum Sander Series

- Saw Series

- Planer And Thicknesser

- Finger Joint Machine

- Press Machine

- Spindle Moulder

- Mortising Machine

- Knife Sharpening Machine

- Board jointing machine

- Wood lathe machine

- Gluing Machine

- Combination machine

- Other woodworking machine

- Woodworking Tool

Product recommended

Hotline:

86-532-80999854

Email: 86-532-68067870

Phone: 0086 18661846170

QINGDAO:12A04-2, Building A, Nuode Plaza, Shibei District, Qingdao City, Shandong Province, China

GUANGDONG:No.22-5, Industrial Zone Road, Xichong Village, Lunjiao Street, Shunde District, Foshan City, Guangdong Province, China

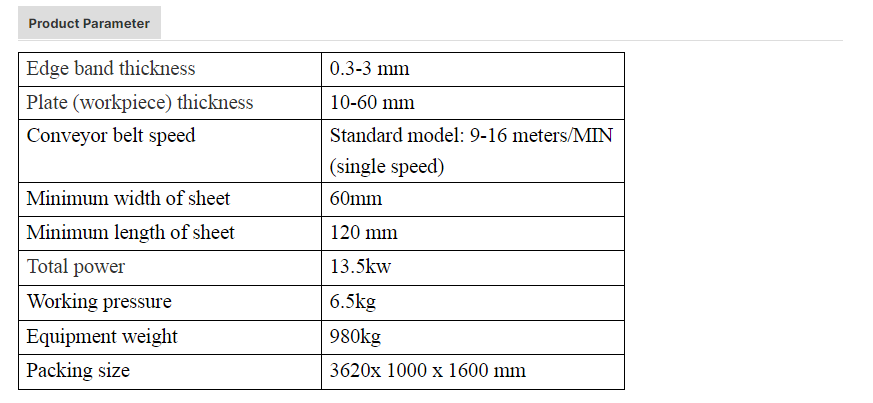

MFZ280Y Edge banding machine

- Application:The machine is suitable for such plates: MDF, block board, solid wood board, particleboa

- Hotline: 86-532-80999854

- Fax: 86-532-68067870

- Email:vivian@kingiso.com

Detail

Contact Us

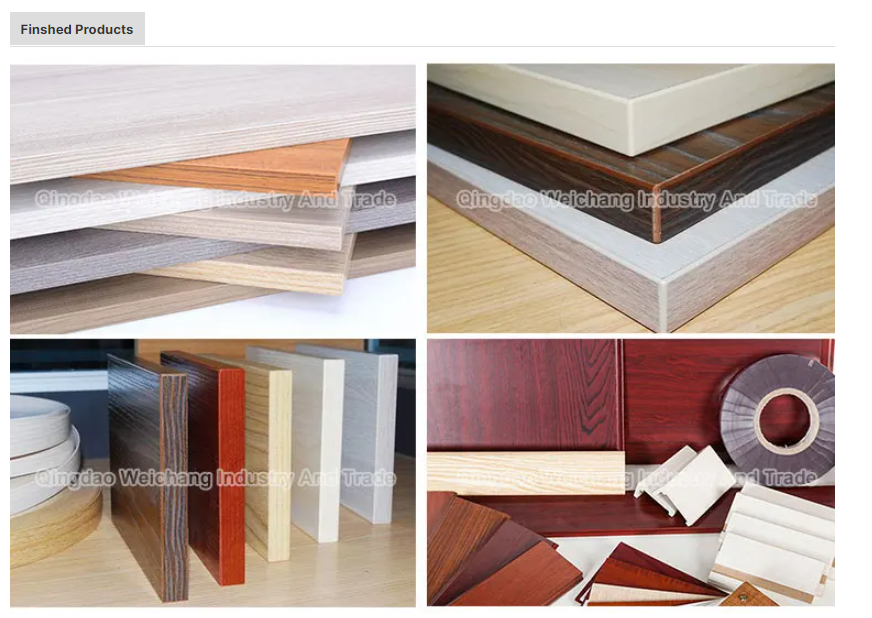

Application:

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc, straight line edging and trimming. Function: pre-milling,gluing,edge cutting,end trimming, rough trimming, fine trimming, corner trimming, scraping, buffing, slotting and so on. Edging smoothly and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers.

Features :

1.This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important factors for an equipment to be part of production line.

2.Pre-milling equipment with double trim-blades works on the waved effect that is caused by precise saw.

3.The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

4.Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc.

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.